Apothecon’s manufacturing ecosystem is designed to scale scientific breakthroughs into global solutions. With specialized API blocks, formulation units, and centralized warehouses, we deliver high-complexity products with speed, compliance, and consistency. Our sites are backed by robust process controls, global certifications, and digitalized systems like eQMS for continuous quality assurance.

Trusted Globally, Certified Universally

Our facilities are audited and approved by leading regulatory authorities, enabling us to serve regulated and emerging markets with confidence and consistency.

Formulation

Our manufacturing operations adhere to the highest international quality standards and regulatory benchmarks. Every formulation — from oral solids to injectables and nasal products — is developed and produced in facilities compliant with USFDA, UK MHRA, and WHO-GMP standards.

Oral Solids

Oral Solids- Extended-release tablets

- Mini-tablets, MUPS (multi-unit pellet systems)

Liquid Injectables

Liquid Injectables- Microsphere formulations

- Lyophilized powders

- Peptide-based injectables

Nasal & Topical

Nasal & Topical- Device-based nasal sprays

- Gels and emulsions

Oral Liquids & Suspensions

Oral Liquids & Suspensions- Device-based nasal sprays

- Gels and emulsions

Pre-filled Delivery System

Pre-filled Delivery System- Auto-injectos, nasal applicators and autopens in the pipeline

Oral Solids

Oral Solids- Extended-release tablets

- Mini-tablets, MUPS (multi-unit pellet systems)

Liquid Injectables

Liquid Injectables- Microsphere formulations

- Lyophilized powders

- Peptide-based injectables

Nasal & Topical

Nasal & Topical- Device-based nasal sprays

- Gels and emulsions

Oral Liquids & Suspensions

Oral Liquids & Suspensions- Device-based nasal sprays

- Gels and emulsions

Pre-filled Delivery System

Pre-filled Delivery System- Auto-injectos, nasal applicators and autopens in the pipeline

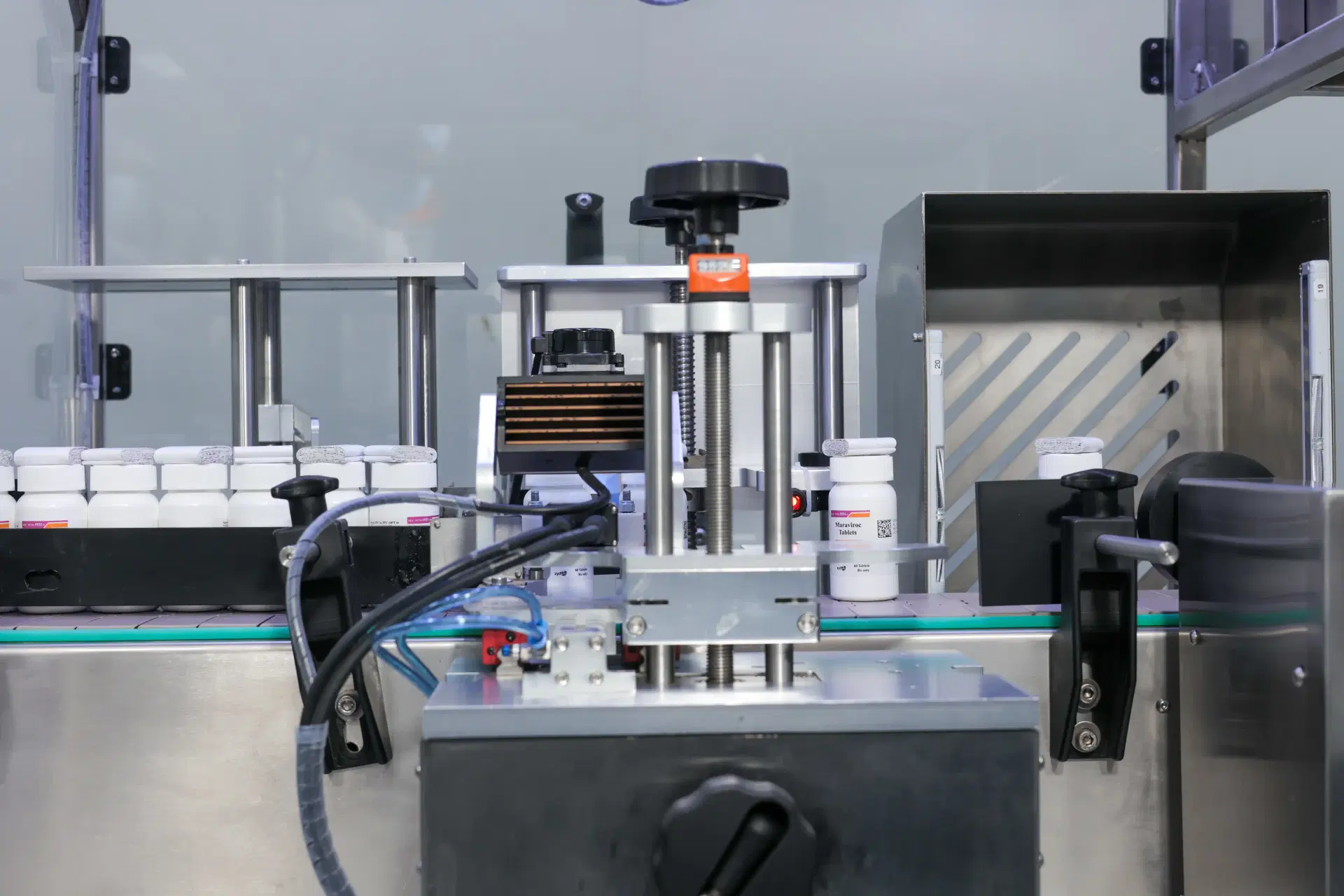

Formulation Production

Apothecon’s formulation facilities are designed to translate scientific innovation into scalable, compliant, and high-quality products. Each unit is purpose-built to support oral solids, injectables, and nasal formulations — ensuring seamless technology transfer, rapid scale-up, and global regulatory compliance.

Advanced API Infrastructure

for Complex Chemistry

Apothecon’s API manufacturing is each equipped with purpose-built facilities for seamless scale-up, safety, and compliance. From early-stage intermediates to peptides and high-complexity APIs, we produce with quality and flexibility at the core.

SVAPI I & II

Purpose-built for niche, small batch, and high-potency APIs.

- Designed for small-volume, high-potency synthesis

- Segregated handling systems and containment controls

- Suitable for cytotoxics and specialized therapies

- Controlled environment for potent molecule handling

- GMP-compliant with strict SOP governance

Quality Standards & Compliance

Our manufacturing operations adhere to the most stringent international quality standards and regulatory requirements.

Trackwise eQMS

International Conference on Harmonisation standards for pharmaceutical development

SAP ERP

Global SAP ERP for supply and production oversight

WHO-GMP, FDA and MHRA-compliant

European guidelines for sterile medicinal products manufacturing

SAP ERP

Global SAP ERP for supply and production oversight

WHO-GMP, FDA and MHRA-compliant

European guidelines for sterile medicinal products manufacturing

Trackwise eQMS

International Conference on Harmonisation standards for pharmaceutical development

SAP ERP

Global SAP ERP for supply and production oversight

WHO-GMP, FDA and MHRA-compliant

European guidelines for sterile medicinal products manufacturing

SAP ERP

Global SAP ERP for supply and production oversight

WHO-GMP, FDA and MHRA-compliant

European guidelines for sterile medicinal products manufacturing